Armed Forces

Polish Cannon Barrels from HSW: Manufacturing Capacity Established

Investment related to modernization and expansion of the new barrel manufacturing facility has been at last completed, at the Huta Stalowa Wola plant. The final step – test firing the first locally manufactured barrel for the Krab howitzer, is just one process-related operation away. Then, the only thing left to be done is to initiate serial production. This is the decisive step along the way, thanks to which the company would no longer act as a barrel importer, in order to transition to the exporting role.

Modernization of the barrel manufacturing facility, the goal of which would be to equip the said department of the factory with competencies and technologies required to manufacture the 155 mm L52 barrels, became an unexpected effect, imposed by the circumstances emerging, caused by an interruption of the Regina programme. The initial assumption was that procurement, in July 1999, of the license concerning the AS90 SPH featuring a 52 calibre-long barrel would become the first step of the way towards an in-depth collaboration seen between HSW S.A. and the British licensor. Integration of Gliwice-manufactured Kalina chassis with the howitzer turret systems manufactured at HSW S.A., was all to take place at the Stalowa Wola plant. Cannon, the most sensitive and the most expensive component, was to be delivered by the British Partner: GEC Marconi. As we know, as a result of the decisions independent from the manufacturer, the programme was frozen for many years, and this happened during the phase when HSW S.A. remained virtually ready to initiate series manufacturing of the SPHs, namely after the tests of both Krab examples existing at the time, prototypes 1 and 2, were finalized.

When back in the year 2008 Poland decided to restore the programme, the foreign partner has already left, but still the Poles had two UK-manufactured turrets installed on the Polish prototypes, coming with licensing documentation, allowing the HSW S.A company to manufacture both the turrets, as well as the cannons. Potential required to initiate the production of what could be created by the Polish industry had to be created from scratch. It was rightly assumed that as the programme was running late anyway, the failure should be turned into a success. Instead of establishing further cooperation connections with new foreign partners, it has been decided that manufacturing capacity shall be restored or created within the domestic industry. Foreign companies were only to provide components that cannot, for a number of reasons, be delivered by the Polish entities, or in case of which manufacturing them locally would be financially unjustified. Rational nature of the above reasoning resulted from an analysis of the capacity of the Polish industry, quite significant at the time already, e.g. in the area of electronics.

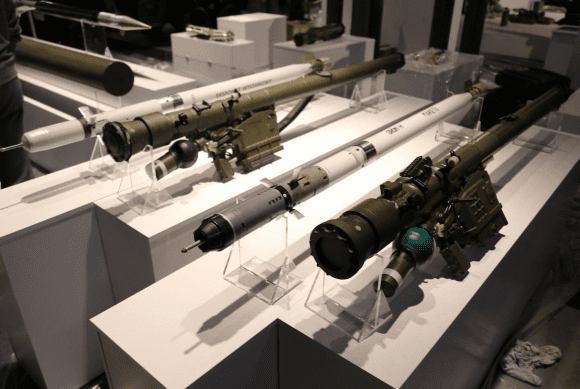

Even though HSW has been able to easily grasp the manufacturing process concerning the turret bodies, and integrating those bodies with the new electronics, manufacturing processes related to production of the cannon itself seemed to be an impermeable barrier, with particular emphasis placed on the barrels. Never in the past have barrels conforming with the expected specification been manufactured here. 122 mm barrel (for the 2S1 Gvozdika howitzer) and the 140 mm ones (WP-8z 140 mm commando rocket launcher and WM-18 140 mm landing craft rocket launcher) were the largest ones, dimension wise. When it comes to length, the maximum value of this parameter was being attained in case of the D-10T 100 mm main battle tank cannon. Manufacturing of weaponry and cannons of smaller calibres, from 35 mm (KDA-35), through 98 to 120 mm (98 and 120 mm mortars) was not a problem, same applied to the 122 mm towed howitzers that had been offered by HSW earlier, or to the 85 mm and 100 mm anti-aircraft and anti-tank guns and 122 mm howitzers. Some products, such as the 100 mm main battle tank cannons, were mass manufactured up until the 1990s, not only to was this done to meet the demand created by the T-54/55 factory based in Gliwice (where around 6.5 thousand tanks of this type were rolled off the production line), but also for the foreign users of this family of tanks. Gvozdika SPH barrels were also being exported.

The challenges applicable to 155 mm 52-calibres long barrel cannons, meaning that the length of the barrel would exceed eight meters, have placed the Stalowa-Wola plant in a completely different place. During the initial phase of works concerning the artillery programme, it turned out that it is required to import virtually all of the cannon components, and to have the most difficult processes delegated to foreign companies. So, creation of own potential should have become yet another step which was to be taken by the HSW plant. This became realistic after the company underwent restructuring, and with the civil manufacturing department being sold to a Chinese investor, in the spring of 2012. The above steps made it possible to obtain significant capital, so important for modernization investments, also in the area of the barrel manufacturing facility.

The strategic goal of the decision to begin the aforesaid works was to be driven towards creation of a modern artillery manufacturing plant for the whole of the Polish industry, remaining capable of supporting the artillery-related orders, within the calibre range between 30 and 155 mm.

The rational nature of this decision did not create any objections or remarks, within the context of the scale of demand created by the Polish Armed Forces, possible to be predicted, with regards to tube artillery systems, and within the context of the cost of barrel acquisition, concerning those systems. Besides the 155 mm L52 systems (Kryl and Krab) and Rak mortars (so far - 64 wheeled chassis mortars, with a prospect of doubling the quantity in a tracked variant), and manufacturing of the 35 mm cannons for the Tryton naval systems and for the purpose of the Noteć air defence programme, it was also assumed that HSW S.A. could become a participant of the programme, the goal of which would be to modernize the Leopard main battle tanks and their 120 mm cannons.

Alongside two of the oldest prototypes (with complete turrets delivered by the British), the howitzers created for the purpose of being used by the first, 8-cannons module (unit), delivered to the Polish Armed Forces in November 2012, were fitted with imported barrels. In case of the 16 remaining Krab SPHs of the first Regina unit, which now are at the stage of final deliveries to the 11th “Masurian” Artillery Regiment, the barrels have also been provided by foreign partners.

At this stage of the Regina programme, it was assumed that barrels for the 12 Krab howitzers of the first out of four Division-level Fire Modules, would also come from the same source. The howitzers in question were contracted in December last year. An assumption was made that launching all of the devices and systems of the new barrel centre may face some delays, which should not be a surprise, concerning the convoluted nature of the undertaken effort. Notably, a technology of autofrettage, never before utilized by the Polish industry in case of barrels of this calibre, has been applied. The said technology is aimed at reinforcement of the internal surface of the barrel, implemented through a process causing internal portions of the part to yield plastically, changing the crystallographic structure of the material. The process is pressure-based, with the pressures reaching the level of 7 to 8 thousand bar. Contrary to the commonly applied bore-hardening methods, taking place by shooting a proper round through the barrel, neither does autofrettage require a so called binding cannon to be used, nor is it required to apply a special stand. Moreover, there is no need to transport the gun to the firing range. The operation is monitored by a system of CCTV cameras and computers, and it takes place within the barrel manufacturing plant, on a special station created below the level of the floor, secured with a cover, close to the remaining processing systems. Thanks to the above, the barrel is being carried to this station only via a single operation.

The autofrettage process’s application is not limited to the 155 mm howitzer barrels. The same technology has been used, within the scope of implementing the process for other barrels, in case of the ballistic barrel created for the Military Institute of Armament Technology, for the purpose of being used in case of the research station at the Institute’s Dynamic Research Facility in Stalowa Wola. The aforesaid barrel is going to be used, among other purposes, for testing the Rak mortar system ammunition.

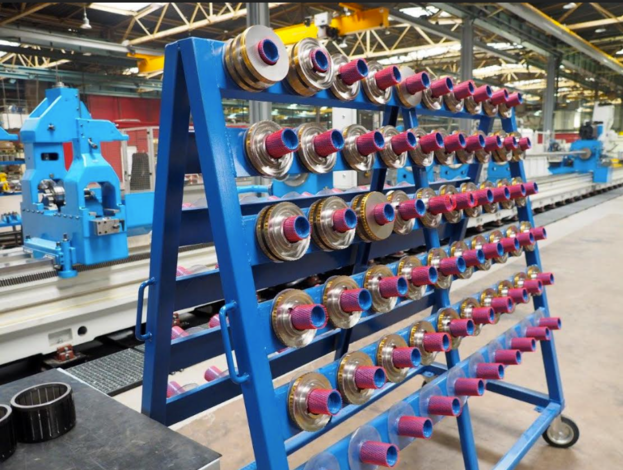

The processing machines of the latest generation installed within the barrel manufacturing facility are a novelty for the Polish industry, making it possible to create precise boreholes with lengths exceeding 10 meters, rifling and honing of the elements, with internal diameters of up to 800 mm. Moreover, a multifunctional miller-lathe system, allowing the user to carry out several operations on a single mounting of the material, without a need to replace it and attach it on different machine, and without a need to carry out time consuming measurements, is also a valuable asset. The above devices cut the production time and costs, and diminish the risk of emergence of set-up errors, also limiting the space required to establish the whole line within the production facility, replacing several costly machines that would require numerous employees to work with them.

When the first barrel of the Krab SPH, created from a scratch at the HSW S.A. facility, would be test fired? This may happen in a few weeks. Rifling, which is quite complex operation, is the last step remaining to be done. This is done through creation of a threading inside the barrel, contributing to the longitudinal axis rotation of the fired round. Rifling is the final operation of the barrel-manufacturing process. This step is carried out through broaching, with 53-56 precise tools being used, each of which cuts a layer of metal.

This phase of processing has been put on hold, after an analysis was carried out, following a test processing done on a specially acquired 4000 mm long material. The said element was used to test all of the operations, before a decision was made that a test barrel would be created out of the costly metal block. Thanks to the above, the risk of making an error has been diminished. After the final processing of the test barrel, it would then be test-fired at the range. The positive result of the tests concerning the first barrel completely manufactured at the Stalowa Wola facility would mean that the new department is ready to start series production of the critical component of the Krab howitzer, which was the assumed goal: to manufacture the barrels locally. Obviously, the above would also remain applicable in case of the Kryl SPH barrel, should a decision be made to initiate series manufacturing of this platform. One may say now that, for the first time since the 155 mm tube artillery programme has been re-initiated, there are some real chances that the cannons would be manufactured in Poland in their entirety.

The deliveries of the Krab howitzers of the module, which is to be the first one of the December 2016 contract, are planned to take place in the year 2018. The above means that introduction of series manufacturing of barrels for those cannons would have to be carried out with a strong emphasis placed on timely execution of the process. This should be understood as follows: at the moment no further plans have been made to acquire mechanically processed barrels for the Krab SPH abroad.

In order to obtain full process-related independence in the domain of barrel manufacturing pertaining to the largest calibres, HSW S.A. would have to take the final step and eliminate the import of the semi-finished products that are used to produce the barrel. Unfortunately, metallurgy department has been closed in case of the HSW S.A. facility, which took away the ability to melt the metal, properly and freely stamp it, to finally put it through the important stage of heat treating. Not only do the semi-products available in Europe have proper physical and chemical properties (alloy composition, structural homogeneity), but they are pre-processed mechanically, externally and internally (pre-turned and pre-drilled). The price of such components is a trade secret, hence it remains quite difficult to publicly discuss the economic limits of investment, allowing the entity to eliminate the need to procure such semi-products at specialized European companies, with only a few of such companies remaining in existence.

At the moment, HSW S.A. has no problems in obtaining production resources domestically, in case of the smaller barrels, up to the level of the 120 mm components (Rak Mortar). However, the Rak barrel is 3000 mm long - its length does not exceed 8000 mm, as it happens in case of the howitzer part. Mastering the production technology concerning the 155 mm barrels intermediary products would undoubtedly place the Polish metallurgic entities in the same league as the global leaders in the field, nonetheless this is impossible without making a number of investments, for example in order to properly carry out the heat treating of semi-products this large.

Production of a cannon which is to become the primary armament of the ZSSW-30 turret module would become yet another chance to expand the potential remaining at hand of the barrel manufacturing plant. The said turret system is expected to be utilized in case of the Rosomak APC and later, in case of the Borsuk IFV. If rights for manufacturing are acquired, an important and attractive product will become a part of the offer of HSW and PGZ. Technologically, as the management of the HSW S.A company suggests, the facility is able to face any challenge.

Jerzy Reszczyński