Armed Forces

Krab, Tracked-Chassis Rak and Baobab-K. HSW’s Booth at MSPO

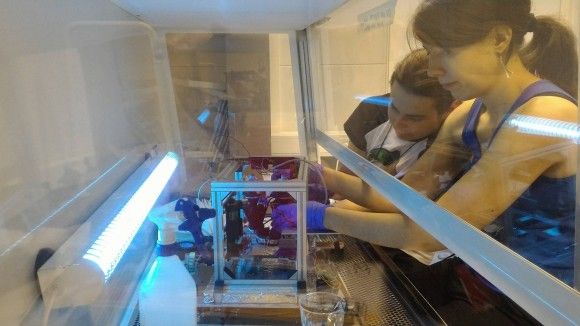

Huta Stalowa Wola, during the MSPO 2016 event, showcased its Krab self-propelled howitzer based on a new chassis, along with a Baobab-K mine-laying platform. Moreover, the company also presented the Rak Self-Propelled Mortar based on a tracked chassis.

Krab self-propelled howitzer is a system which is said to be capable of attacking targets at distances of up to 40 kilometres, offering an ability to have the first three rounds fired in 10 seconds, starting from the decision to begin the potential artillery strike. The howitzer, when on the move, reaches the readiness for combat in about 30 seconds. Leaving the firing position also takes no more than half a minute. The vehicle is capable of firing the projectiles straight ahead too. Krab has been fitted with a fire control system, internal and external communications suites and a land navigation system. The platform has a combat weight of 48 tonnes, and it has been fitted with the MTU 881 Ka 500 engine, the maximum power output of which is defined as 1000 HP.

Huta Stalowa Wola, at the moment, is in the process of delivering 24 Krab self-propelled howitzers for the Polish Army. In August, another six howitzers were assembled at the HSW facility, as it was declared by the Head of the Armament Inspectorate, brig. general Adam Duda. The agreement related to more fire-units (referred to as fire-modules) – probably four – is planned to happen until the end of this year. In this way, the Polish artillery would obtain, in total, 120 modern 155 mm self-propelled howitzers. This number is higher from e.g. quantity of howitzers that are to be utilized in the target structure of the Bundeswehr (101 PzH 2000 systems).

HSW also showcased its Baobab-K mine-laying platform based on the Jelcz 6×6 truck. The system has also been developed with the Polish Territorial Defence elements in mind. At the moment the Polish Army has only a minor quantity of the Kroton mine-layers at its disposal, with the platform being based on a tracked chassis. At the same time, it is said that having an ability to rapidly create the minefields is crucial, when it comes to hampering the movement of the enemy armoured and mechanized units.

Baobab has been fitted with an onboard computer coupled with a visualization system and a digital map. In conjunction with the GPS navigational suite, the above set of equipment allows the vehicle to lay the mines in an automatic mode, within the framework of the programmed set-up, also when it comes to the frequency at which the mines shall be launched when the vehicle is on the move. Moreover, location and parameters of the newly established minefield are presented via the visualization system, and the relevant data may be then transferred upwards the command chain.

Baobab-K also has an ability to lay the mines in a manual mode. Total mass of the vehicle does not exceed 21.02 tonnes, including mines. The truck is 9.4 meters long, and, respectively, 2.55 meters wide when on the move and 2.85 meters wide when the mine-laying process is carried out. Two variants of the Baobab-K system are under development now – the one presented at the MSPO event, featuring four mine-launchers, and another one, which utilizes six systems of this kind.

On the other hand, the self-propelled Rak mortar was showcased, during the MSPO event, in a version based on a tracked chassis developed by HSW. This derivative variant of the Rak system is dedicated, above all, to be used by the brigade elements, the core of which is to be formed by the main battle tanks and infantry fighting vehicles. In the future, the current chassis will probably be replaced with the very same platform which is going to constitute a replacement for the BWP-1 infantry fighting vehicle.

Tracked Rak mortar features the identical autonomous turret module, as the one used in case of the Rosomak APC platform. The above means that the mortar based on a tracked chassis has been fitted with a fire control system along with a ballistic computer and external and internal communications suite, complemented with a 360 degrees observation suite and optoelectronic targeting device for shooting in the straight ahead direction, featuring a laser range-finder, with a range of 10 kilometres.

Meanwhile, works are being carried out, the aim of which would be to finalize the contract concluded in April 2016, pertaining to delivery of the vehicles for eight company-sized units of mortars based on the Rosomak APC platform. The agreement, at the moment, assumes that 64 mortars are to be procured, along with the command vehicles. The platforms will be used by the brigades that are armed with the Rosomak APCs at the moment.