Armed Forces

Laser Guided Munitions. Is the Polish Artillery Going to Remain Blind?

The contract signed back in 2016, with the MESKO company, envisaging delivery of 1300 missiles and 420 launchers for the “Piorun” MANPADS system is a good example the Polish MoD has set, by providing constant financing for the Polish defence industry, with the Polish military benefiting from the above, as it is receiving modern armament systems. A similar approach shall be taken with regards to the Polish laser-guided ammunition and laser target designators. Otherwise, the Polish industry would lose its manufacturing capacity, while the procurement will need to be done abroad, within the framework of the “urgent operational requirement procedure”.

The agreement has been signed by the Armament Inspectorate with the Mesko S.A. company on 20th December 2016, assuming that 420 “Piorun” MANPADS launchers and 1300 missiles would be delivered to the Polish military by the year 2022. Procurement pricetag? PLN 932 million. Thanks to the contract above, concluded in the aforesaid manner, the Polish industry can acquire proper components in advance, also supporting the production line and employment and continuing the R&D related to the missile.

Read More: Poland Spends PLN 1 Billion to Cover Procurement of the Piorun MANPADS. JASSM-ER Deal Closing In

The decision made by the MoD back in 2016 also has quite positive impact on the military. The armed forces receive a weapons system systematically and in large quantities, instead of getting it as a result of single source procurement procedures, in small numbers. This would accelerate and systematize the modernization of the Polish Army’s air defence assets, also simplifying the operational use of the “Piorun” missile. There will be no need to modernize or withdraw them in large quantities, as this process could be distributed along a longer timeline.

The industry benefits from that as well, obtaining new know-how. The use of that expertise will only be possible when contracts made in a manner identical to that applicable to the “Piorun” missile are concluded. Precision laser guided munitions are a good example here. Manufacturing of such munitions can be quickly launched in Poland. However, the MoD has not made any decision within that regard as of yet.

Why the Polish military would need the precision guided rounds?

The Joint Fire Support doctrine assumes that use of all assets on the battlefield is done in a coordinated and integrated manner, this also applies to PGMs used by the air force, Navy and by the land component. However, the doctrine in question is not common in Poland. The Air Force is the only branch of the military using non-rocket precision guided munitions. And nothing suggests that a change is coming soon.

The above applies to rocket armament as well. Theoretically, guided weapons are available to the Navy and to the Land Forces (following the introduction of RBS-15 anti-ship missiles on the Orkan-class vessels, NSM missiles of the Naval Missile Unit and procurement of the HIMARS ground-to-ground system for the Army). Fire support carried out with the use of expensive anti-ship missiles (RBS-15, NSMs) shall be viewed as a last resort and it should only be used against high value targets. Meanwhile, the quantity of procured HIMARS rockets would not allow for common use of this asset to directly support the land forces.

Task as such may be carried out with the use of precision-guided artillery rounds. These rounds need to be as cheap as possible, so that they are available in high quantities, it would be optimal if they are made in Poland. As there is no chance that Poland would be fully autonomous in manufacturing GPS-guided rounds, the industry is focused on laser-guided solutions as such.

Round as such uses INS guidance at first, and during the terminal phase it detects the laser designator light beam reflected by the target directly. To make this possible, the nose is explosively removed in flight, exposing the guidance sensor. The guidance systems are designed to receive the encoded signals emitted by the designator that is turned on when the round is 2-3 kilometers from the target.

As it turns out, the Polish industry remains capable of designing and launching production of such rounds. However, this task has not been defined as a priority.

Meanwhile, solely the precision-guided munitions make it possible to rapidly destroy the indicated threat at a low cost with minimized collateral damage. The latter condition must be met in urbanized areas. Obviously, the Land Forces have the forward artillery observers at their disposal (WOA). Contrary to Air Force’s JTACs and TACPs, the Polish WOAs work in a manner similar to the one we were witnessing during the WWII. The only difference is the array of means of communication and observation. Contrary to JTACs, WOAs do not use laser target designators of any sort. Instead they only have artillery observation/reconnaissance instruments at their disposal, fitted with laser rangefinders.

This is logical. The Polish tube artillery units do not use laser guided rounds (this includes Krab 155 mm sphs and Rak 120 mm mmortars). Meanwhile, WR-40 “Langusta”, BM-21 “Grad” and RM-70 multiple rocket launch systems are still using 122 mm unguided rockets. Precision guided munitions could be developed domestically for all of the aforesaid systems. Laser target designators, the design of which ensures their universal nature and allows them to guide bombs, missiles and artillery or mortar rounds, could also be manufactured locally.

Obviously, the PGMs are much more expensive than their conventional counterparts. The higher price is compensated with the fact that the rounds are far more accurate. 16 precision guided rounds make it possible to create an effect that is equivalent to 800 modern standard 155 mm rounds. This, automatically, makes it possible to carry out the assigned task 10 times quicker. Thanks to the above the assets may leave the firing positions earlier which protects them from counterfire.

Lower ammunition demand also translates into lower cost of logistics, related to ammunition storage and delivery, and diminished collateral damage, which is especially important during foreign deployments and defensive operations undertaken within own territory. Precision Guided Rounds are much cheaper than missiles or airstrikes, and thus it may be commonly used to saturate even the smallest elements. Furthermore, rounds as such are much harder to neutralize.

Thanks to all of the aforesaid features, precision guided artillery rounds are often defined as a tactical deterrent. The enemy who is aware of the fact that assets as such come into play needs to proceed in a slower, more careful manner which, in turn, gives defenders more time to organize a proper, effective defensive action. Additionally, common introduction of laser target designators would also mean that Poland could receive immediate support from the NATO military aviation assets carrying out precision strikes against the targets indicated by the Polish soldiers. NATO land assets, on the other hand, will need more time to reach the battlefield.

APR 155 Precision Guided Rounds

In Poland, advanced works on such munitions have begun, formally, as late as in 2009. Then a consortium including the Military University of Technology, ZM Mesko S.A. facility and Telesystem Mesko Centre for Implementation and Development, has issued a proposal for the Commander of the Land Forces to introduce laser-guided artillery rounds into use, also proposing that the R&D programme shall concern the 120 mm mortar rounds, 122 mm rounds for the 2S1 Gvozdika howitzer, 152 mm rounds for the Dana howitzers and 155 mm rounds for the Krab howitzers.

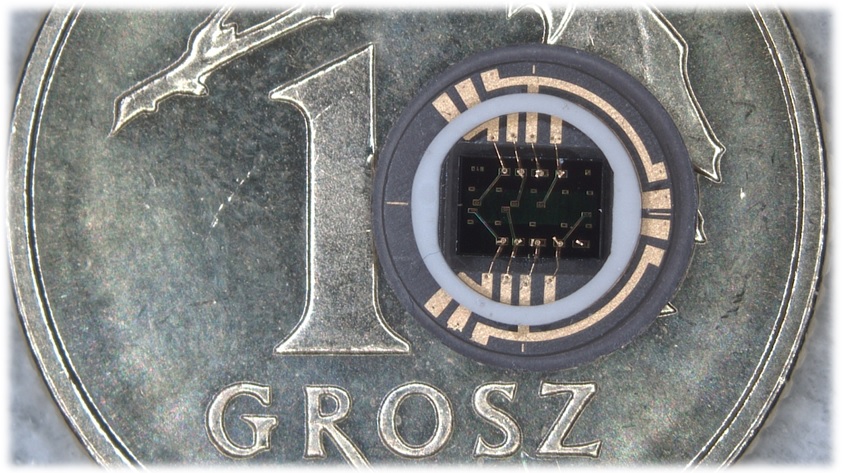

Ultimately, the Telesystem Mesko company was awarded an order to carry out three R&D initiatives in September 2012. The works concerned a laser tracking system for the APR 120 round for the 120 mm Rak mortar, laser tracking system for the 155 mm Krab and Kryl ammunition (APR 155) and a laser target designator designed to be used with both of the aforesaid tube artillery platforms.

To accelerate the programme, given the lack of domestic domain-expertise, it was assumed that a Ukrainian round design would be used as a starting point by the Polish company. APR 155 makes use of some solutions of the Progress “Kvitnik” round based on the Russian 30F39 “Krasnopol” round (according to the Russians; the Ukrainian claims are exactly opposite). The situation is different when it comes to the APR 120 mortar round. It had no Ukrainian counterpart. For that reason it was being designed, since the very beginning, by the Polish engineers and Ukrainian specialists hailing from the “Luch” company, from a scratch.

Direct copying of the Ukrainian solutions did not take place, as three millimeter calibre difference (155 mm NATO round vs 152 mm round) also creates a significant G-load differences - even of several thousand Gs. Thus extra design effort turned out to be required in case of the APR 155 round. The Ukrainian engineers also had to take weight distribution and aerodynamics in case of the 155 mm calibre. Then they have sold the 155 mm rounds documentation to Poland, with the changes already implemented. The documentation also included the guidance unit design which is a benchmark for the serious approach the Ukrainian industry adopted, when it comes to collaboration with Poland.

Even though the general mechanics could be adopted for the APR 155, the Polish designers did not use the Ukrainian solutions within the scope of electronics, developing a similar, yet indigenous guidance system. Thanks to the above, the Polish digital solution can use NATO encoded data - in case of the Ukrainian rounds this has not been possible, for obvious reasons. The success achieved by the Polish designers is even more significant, considering the fact that the Ukrainian industry has not yet been able to digitize its guidance units, even though it is quite advanced in the domain. The Poles have also modified the optics and the sensors of the round. They have created their own, original autopilot solution along with a domestic laser target designator design.

The results have been then tested in Ukraine - as Poland has no test benches at its disposal to simulate 10000 G loads - ones that are expected in case of the 155 mm rounds. During the first tests it has turned out that the Polish digital solutions survived the procedures without any problems, which surprised the experienced Ukrainian experts.

Field tests were equally successful. APR 155 prototype rounds were fired on 18th November 2016 at a distance of more than 15.3 kilometers. Despite the heavy wind conditions, the rounds have hit a target of dimensions of 2x2 metres, with 0.3 and 0.6 metres deviation from the target (with the designator located 500 metres from the target). Ukrainian semi-active 9E421 seeker has been used at the time, while the LPC-1 designator was operated in neutral mode.

Operational APR 155 round is to be fitted with a Polish programmable digital guidance system coupled with a domestically developed sensor. This would make it possible to use a NATO-standards-compliant encoded beam. The companies involved in the programme were declaring their readiness to begin manufacturing of the round in 2020. Declarations as such were being made back in 2018.

According to the standard division of expertise, Centrum Rozwojowo Wdrożeniowe Telesystem-Mesko works on the guidance unit, while MESKO develops the warhead and the propelling charge. GAMRAT company has delivered the extra propellant, while NITRO-CHEM has provided Mesko with a 8 kg explosive charge. The whole round is to weigh 48 kilograms and have a range exceeding 20 kilometers.

APR 120 Precision Guided Rounds

APR 120 mortar rounds are even more advanced, when it comes to their development. This ammunition is destined to be integrated with the Polish “Rak” self-propelled automatic mortar. The AP round that is 800 mm long ad that weighs 16.8 kilograms (120 mm calibre) is to be used for precise neutralization of armoured targets at distances of up to 8 kilometers, with those targets being attacked from the topside - the weakest point of the turret and of the hull. APR 120 has been fitted with a single stage shaped charge warhead. Its performance “satisfies” the demands made by the military. Option of creating a HE variant of this round is also being considered.

APR 120 design effort was more challenging than the same process pertaining to the APR 155, based on the operationally used Ukrainian 152 mm rounds. APR 120, starting from the concept phase, was being developed by a joint team of Polish and Ukrainian experts. The Poles decided to design the front section electronics, while the Ukrainians were tasked with developing a control system.

Initially it was assumed that a guided bomb-like system would be used for that purpose. However, length limitations made the above impossible (ca. 800 mm). That limitation stemmed from the fact that the round was to be accommodated within the “Rak” mortar’s autoloader system.

The Poles proposed that an inertial guidance system is used instead, with the round itself becoming a gyroscope, with the optical system becoming fixed (changed design). APR 120 became a unique, Polish-Ukrainian solution, having no counterpart anywhere in the world. Solely Israel uses a similar gyro-less electronic guidance solution, in case of which the round rotation is stopped, contrary to the Polish system.

Not only is the APR 120 round stabilized, it is also a laser-guided projectile. If the Polish-Ukrainian guidance system passes the test programme successfully, PGM application included, then guided mortar rounds can enter production as early as in 2021.

“Pirat” ATGM

When a light laser guided ATGM concept was developed in Poland (named “Pirat”), the assumption was that it would fill in the gap between grenade launchers and Spike ATGMs. Low price was also an important factor here.

The new armament is developed by companies teaming up to carry out the joint effort. The entities involved include: MESKO S.A. (main contractor), CRW Telesystem-Mesko and Military University of Technology. The effort makes use of the experience gathered by the Ukrainian KKB Luch company, when developing the R-3 “Korsar” system ATGM. Furthermore, the Polish design makes use of some solutions we have seen in case of the Grom MANPADS guidance unit.

The implementation mentioned above was required, as “Korsar” class solution belongs to the group of “beamriders” (LOSBR ATGM - Line-of-Sight Beam Riding). “Pirat”, meanwhile, is to be guided towards reflected laser beam originating from a laser target designator. “Pirat” uses a semi-active laser seeker unit, contrary to the R-3 missile that has a precursor fitted to the front section of its body. All of the above is a result of application of a beamriding guidance system. According to the assumptions, “Pirat” is to weigh 10.1 kilograms, with a 107 mm diameter and 1180 mm length. It is going to be carried and stored in a container weighing 3.4 kilograms.

The field tests have shown that “Pirat” has a range of around 2500 metres (12 seconds are needed to reach the target). At the moment the research is focused on a missile fitted with an anti-tank shaped charge warhead weighing 2.5 kilograms and being capable of penetrating up to 500 mm RHA armour - it is suitable for destroying older MBTs, APCs and IFVs. Pirat can also be fitted with a Frag-HE and thermobaric warheads. According to the assumptions, the missile is also to be used together with a laser target designator fitted to UAVs.

Despite the fact that MESKO is still working on the launcher, the company has made declarations that series manufacturing could begin in 2020, with regards to the “Pirat” missile. No official orders have been placed by the Polish MoD, with regards to the above armament.

Laser Target Designators - Ready to be Introduced

Not only is Poland working on laser-guided munitions, as it has also developed a domestically developed laser target designator that also allows for measurement of target distance (thanks to a laser rangefinder with a range of up to 20 kilometers), defining own position (GPS) and bidirectional data exchange with the C2 system (with an ability to send status reports, target positions and also offering a remote control ability from the command centre). The system also allows to define the target azimuth and elevation as it can be coupled with a goniometer.

The device has been developed by Telesystem Mesko and is ready for production, under the LPC-1 designation. It is enclosed in a cuboid housing with dimensions of 126×377×258 mm. It weighs 9.7 kilograms on its own. CRW Telesystem Mesko declares that the device may be made more compact, depending on the user requirements.

LPC-1 system uses a neodymium-yag (Nd:YAG) laser with a wavelength of 1.064 μm, emitting an encoded signal made out of 15± 5 ns impulses. Therefore this signal is only readable for the missile seeker. PRT sequence can be programmed in line with the NATO STANAG 3733 document. This may be done remotely, with proper data automatically provided by the fire control centre, or manually by the operator, with the use of digital knobs on the rear plate of the device, on the basis of the radio-transferred information.

The targeting module can be replaced (optical sight, daytime camera, thermal camera or NVG system). It is fitted onto a Picatinny rail, compliant with the STANAG 2324 norm. The system is controlled via the means of embedded OLED display that informs the user about the control mode (remote/manual) and provides him with the measurement data.

Is it possible that we would see common use of PGMs in the Polish military?

Launching a programme aimed at equipping the Polish military with laser-guided munitions requires an attitude to be adopted that would be similar to the approach the MoD took with regards to the “Piorun” MANPADS. Obviously, laser-guided rounds are much more expensive, when compared to their standard counterparts. However, one shall remember that APR is, in fact, a missile, with its own guidance and propulsion units.

Introduction does not necessarily need to involve a single procurement of a large quantity of rounds. Systematic acquisition of at least 200 rounds per year would make it possibe for the industry to ensure sustainability and carry out further development of the said armament. Positive results that the aforementioned approach may render can be seen in case of the five-year term “Piorun” MANPADS agreement. The decision made by the MoD enabled the industry to plan the production over a longer timeline which also diminished the cost of acquisition.

Similar savings can be made in case of a long-running laser-guided PGMs procurement. Compared to their western counterparts, munitions as such would be several times cheaper, offering better or equivalent performance. APR and “Pirat” programmes can also be treated as a source of prospective know-how.

Here we can refer to the example set by the APR 120 IMU system that can be used in case of any other round. It is, according to the Polish engineers, more precise than the system used in case of the US-made HIMARS solution. “Luch” and “Pivdyennye” design bureaus used this method, introducing a similar set of solutions for their “Vilkha” system based on the BM-30 “Smerch” launcher. Thus they have obtained a 300 mm PGM using a satellite guidance unit.

The very same approach can be adopted in case of the Polish 122 mm multiple rocket launch systems, as a control surface units are available for 155 mm, 120 mm (mortar) and 70 mm (Pirat) calibres. They can be adopted and used to rapidly develop a modernization package for 122 mm “Feniks” HE rockets, transforming them into a precise asset that would be much cheaper than the HIMARS effectors. Rafael company has developed an EPIK (Electro-Optical Precision Integration Kit) solution for the 122 mm munitions.

Poland could also select the guidance system type, as both IR as well as laser solutions could be used. APR 155 mm system can also be developed by extending their range through addition of a sustainer motor turning an artillery round into a precise missile with its range being dependent on the motor used, the development of which can be carried out by the Polish industry. Thus the Polish military would receive a counterpart of the Hellfire ATGM, with a slightly shorter range.

The technologies created during the “Pirat” programme could also be utilized for the purpose of enhancing the capabilities offered by the PK-6 anti-aircraft missile developed by CRW-Telesystem-Mesko jointly with Mesko S.A. “Piorun” missiles, meanwhile, could be modified in a way that would allow them to intercept the targets when airborne. As for now, they need to lock onto the threat prior to launch. The Polish engineers, however, could develop a LOSBR solution and theoretically it already exists in case of the mobile “Poprad” platform fitted with an observation system (radar, cameras, tracker) making it possible to guide the missile towards the target thanks to the beamriding method, until the missile’s own seeker becomes active. This makes it possible to guide the missile in cloudy conditions, as laser beam may be stronger. Loss of the beam is also a minor issue - in circumstances as such the missile would simply activate its seeker to scan the airspace for potential threats. Not ony would the above extend the range, as it would also make the engagements more effective.

If “Piorun” missile is then fitted with a multispectral seeker that has already been developed and is being tested at Telesystem-Mesko (similar to the Russian “Vierba” MANPADS solution), an entirely new weapons system would be obtained, with no counterparts anywhere in the world. The above is possible, as the work on a multispectral seeker unit would be fairly advanced in Poland this year (level 6). This potential could be used - it would be enough to analyze the capabilities remaining at hand of the Polish industry which should be followed by a plan of modernization taking the aforesaid capabilities into account. This should also entail contracts similar to the “Piorun” procurement.