Armed Forces

Automatic AM-35 Naval Cannon System - Navy and Beyond?

35 mm Ship Artillery System had been already mounted and implemented on the ORP “Kaszub” Corvette. Not only will the automatic 35 mm naval cannon be suitable for use in the naval applications, but once the test programme is successfully realized, the weapon will also be useful for other armed services.

The design of a ship-borne 35 mm artillery system has been developed by a consortium, involving the following entities: Warsaw Military University of Technology (Leader), Polish Naval Academy of Gdynia, PIT-RADWAR S.A. company based in Warsaw and ZM Tarnów S.A. company from Tarnów. Works on the maritime 35 mm weapons system are being implemented within the framework of a development project known under the following name: “35 mm automatic naval KDA cannon, with a fire control system embedded within the ship, using an integrated ZGS-158 naval tracking system with a fire control station”. The initiative is being co-financed by the National Centre for Research and Development. The whole process has started on 19th December 2012. Not only may the results of the aforementioned programme be useful for the Navy, as other components of the Armed Forces could also find them interesting.

The basic task for the system is to act against the airborne threats, including drones, and to neutralize the naval targets, including those utilizing light armour. The system, besides the 35 mm cannon, also utilizes a number of other elements which had to be tested and developed. However, in a longer run, it is possible that modifications of the weapons system would be introduced, in line with the needs of the user.

The system’s operation has been initially verified during the live-fire testing, which was carried out at the Central Air Force Range in Ustka, in December last year. Installation and initiation of the system onboard the ORP Kaszub corvette constituted the next stage – it took place in the second quarter of this year. During the third quarter, the system is expected to undergo sea trials onboard the ORP “Kaszub” vessel. The test programme is to be finalized by 18th September 2016. It is assumed that the weapon will be fired, among other targets, at a drone, towed target and a mine imitator.

Not only will the automatic 35 mm naval cannon be suitable for use in the naval applications, but once the test programme is successfully realized, the weapon will also be useful for other armed services.

Division of Tasks Between The 35 mm Naval Cannon Consortium Members

PIT-RADWAR company acts as the main integrator and contractor, working on the system. Within the array of the dedicated tasks, the company has designed and created the following elements:

-

Integrated optronic stabilized tracking unit, featuring optoelectronic sensors and IFF interrogator;

-

Main (primary) fire control station (SKO), along with the dedicated software package;

-

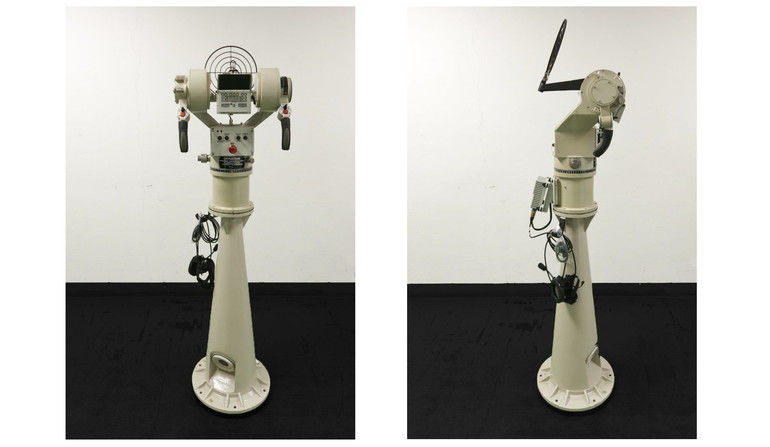

Reserve fire control station (RSKO), also known as a “little column”;

-

Electronic subsystems for the whole system, including the power-supply system, drive and control unit, stabilization system for the rotating part and the head of the cannon, within the azimuthal and elevation planes;

-

Control and user software for the whole system, including the diagnostic software suite.

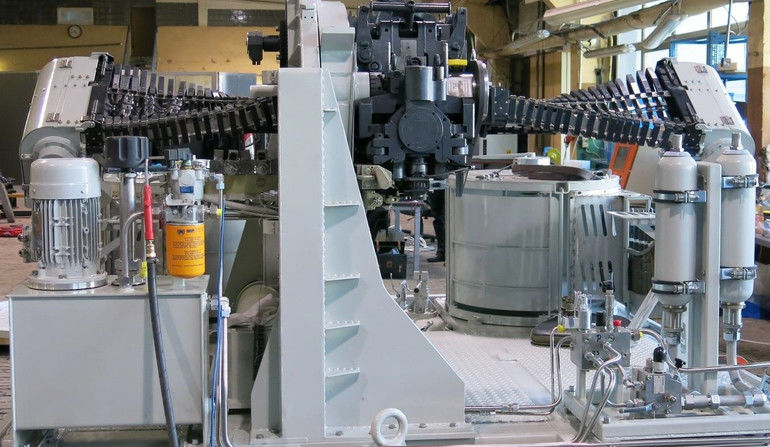

ZM Tarnów company has created the following elements of the system:

-

Mechanical elements and components of the cannon, including the rotating platform and base (rocker), making it possible to mount the 35 mm KDA cannon, along with the auxiliary systems;

-

Control System (UKiSA);

-

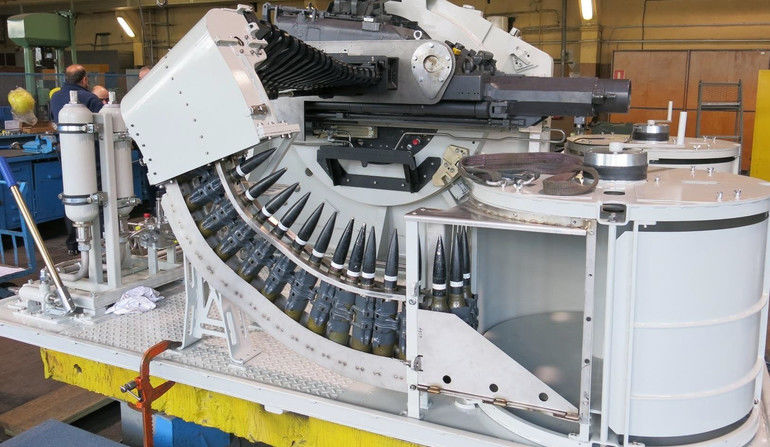

Ammunition storage and supply system for the automatic cannon, along with a hydraulic control system;

-

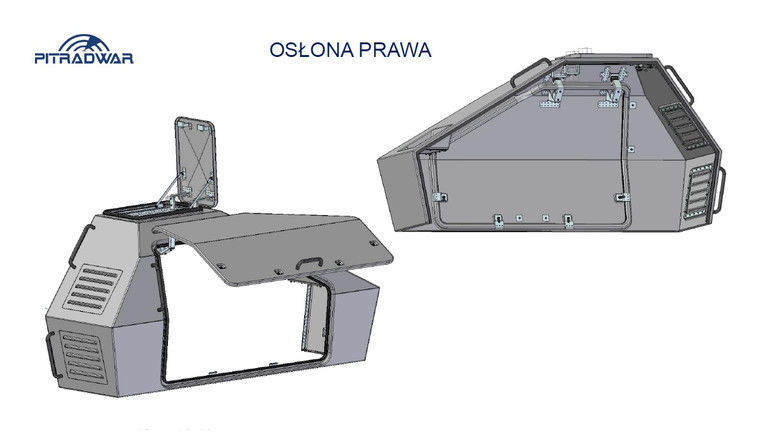

Composite covers for the rotating platform.

During the works, a problem related to precise control of an object of high inertia has been solved (referring to the rotating part of the cannon). Thanks to the fact that modern electric/electronic components, along with drive and control systems have been applied, it was possible to create a stabilized two-axis system for the cannon and for the integrated tracking system. Notably, the system features supercapacitor units, the purpose of which is to buffer the energy within the drive system. Military University of Technology and Polish Naval Academy were to, within the initiative, define the requirements pertaining to “the features and parameters of the ship-based autonomous fire-reconnaissance system”, and to prepare a proposal pertaining to arrangement of the individual elements of the weapons suite onboard the vessels.

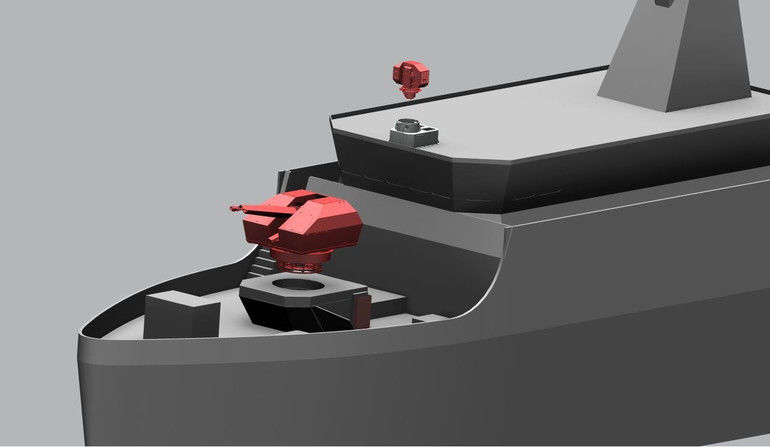

In case of the ORP “Kaszub” corvette, a proposal has been made to remove the stern-mounted ZU-23-2M Wróbel I system, reinforce the deck area of the superstructure, so that it would be able to accommodate the new cannon. Moreover, location has been indicated where the reserve fire control system is to be placed – which required expansion of the navigation deck. Thirdly, a place has been selected to fit in the integrated tracking system and arrange the fire control station’s premises.

The distance between the cannon and the tracking system is relatively long (more than 20 meters), but thanks to the fact that precise inertial navigation systems, accurate cooperation between the cannon and the tracking-targeting system has been achieved. Creation of the structural wiring for the cannon required a number of overhaul and installation procedures to be carried out. This was done by the Gdansk Remontowa Shipbuilding company, following an order placed by the consortium.

Automatic AM-35 Naval Cannon System – Requirements

The requirements that decided on the current shape of the system have been defined by the Polish Navy. The basic requirement defined the modular structure of the AM-35 cannon. Modular structure of the elements of the system should make it possible to install it onboard a variety of the Polish Navy’s vessels, without a need to implement deep structural changes in the deck – e.g. no option existed to bore through the deck outside the scope of wiring, and it was required that no ammunition storage and supply system are installed under the deck. The ammunition storage had to be fitted within the turret, which significantly increased its size. Comparable systems, such as the Russian AK-176 cannon, besides the turret, also take up a lot of precious space below the deck.

Moreover, the Polish Navy's experts have used their experiences gathered during the works on the BLENDA artillery system. The requirements defined for AM-35 assumed that a similar optoelectronic fire control system is applied, which simplified and accelerated the works, reducing their cost. In this way, it was possible to base the design on track-proven and already developed components, and the ordering party could have assumed that the final product is going to have a well-defined and functional nature.

The user also required the system to be scalable (when it comes to expansion of configuration) and open. The Polish Navy’s professionals realized that the budget may not be big enough to create a targeting system different from an optronic sensor. At the same time, it was known that only a radar guarantees that the potential target is detected. Thus, the AM-35 automatic cannon system is designed in an open architecture. It was prepared in a way which makes it possible for it to operate together in an arrangement coupled with radars, including surveillance and fire control radars. At the moment, the naval cannon system has no dedicated battlefield radar at its disposal. It uses other information acquired from the navigation radars embedded within the ORP “Kaszub” vessel. Thanks to the above, the development potential of the newly designed system has been tested. Initial indication of maritime and low-flying targets has also been possible to be achieved.

Automatic AM-35 Naval Cannon System – Components

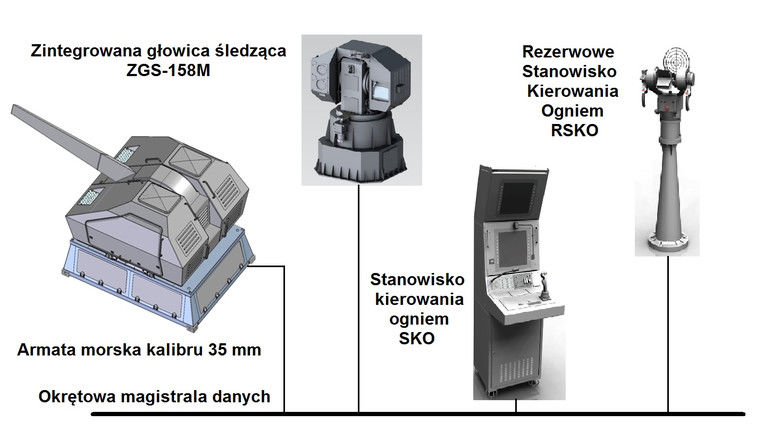

The discussed system features four main modules:

- Automatic 35 mm naval cannon;

- Integrated ZGS 158M optronic tracking system;

- Basic SKO fire control station embedded within a single multi-functional console and controlled by a single operator;

- Reserve Fire Control station, allowing the user to aim the cannon directly, optically, should the SKO suite be damaged.

The creators of the system claim that the 35 mm cannon could have been designed so quickly only due to the fact that back in the 1990s, when RADWAR was working on the LOARA project, it was possible to acquire license from the Swiss Oerlikon company, along with the full rights pertaining to the KDA 35 mm cannon. Up until now, the Polish Army has not been using a high number of weapons systems based on that license, which was procured through spending of significant budgetary assets. As the AM-35 system is introduced into the inventory, the situation is about to change.

The Polish engineers had the KDA 35 mm automatic cannon at their disposal, offering the rate of fire of 550 rounds per minute, with a belt-feeding option at both sides and air-cooled barrel. According to the manufacturer, due to the accuracy of the weapon, it is enough to fire three to five rounds in a burst to hit the target.

The cannon has an effective range of around 5000 meters (for programmable ammunition – the range may be smaller). The barrel may reach elevation angles between -10° and +80°. The turret may be rotated azimuthally within a range of ±175° ( ±130° range was sufficient in case of ORP Kaszub), with a speed of 2 radians/second (around 114 degrees per second). Let us recall the fact that for the purpose of firing the cannon against an airborne threat, flying parallel to the cannon at the distance of 500 meters, at altitude of 500 meters and at supersonic speed of 600 meters per second, a tracking system with rotation speed of 1.2 radians/second is required. The KDA cannon is controlled with the use of a hydraulic system controlled by the UKiSA block (system for control of the cannon, designed and manufactured by ZMT S.A.).

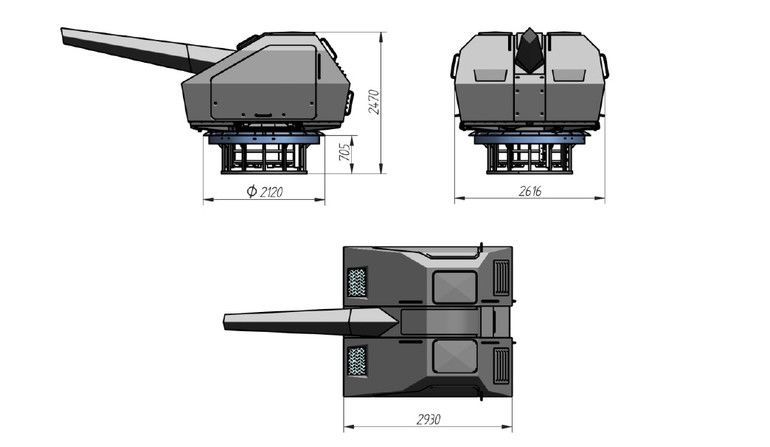

The whole cannon, including the barrel, weighs around 670 kilograms, while the complete turret weighs ca. 3.3 tonnes. Its length is defined as 2.93 meters (without the barrel), it is 2.62 meters wide and 2.47 meters high.

The control system developed by ZM Tarnów makes it possible to load the first round (during shooting the cannon is operated thanks to the gases), release the trigger, program the burst length, select the ammunition storage and monitor the sensors, including the one which detects the round within the chamber.

The cannon’s hatches maximally facilitate the access to the main components, for the purpose of carrying out the potential repairs and maintenance. KDA 35 mm cannon is a symptom of a new philosophy, adopted within the process of designing the artillery systems. This is the first “crew-less” cannon in Poland, since the turret is unmanned.

It was also required to create a new solution when it comes to the ammunition supply. It is a very important issue, considering the crew safety and ergonomics, when at sea. Due to the design features of the KDA 35 mm cannon, the ammunition needs to be belt-fed. Tarnów facility has proposed implementation of two drum magazines (featuring a brake controlling the belt inertia), each of which contains 100 rounds and provides a feed on one side. This makes it possible to differentiate the applied ammo and store e.g. sabot rounds in one drum, as they are effective in neutralizing the “hardened” (also armoured) targets, and programmable rounds in the second drum, as they are effective in neutralizing “soft” targets, such as aircraft.

The experts claim that the programmable ammunition does not have to be used to act against every target, considering the higher cost or mass of the round, with the latter factor having a decreasing impact on the range and speed of the bullet. The 35 mm cannon described here, as compared to the competitive solutions, has an option of selecting the type of ammunition when firing, which has a direct impact on better effectiveness and flexibility of the system, as it is capable of acting against a wider spectrum of targets.

The ammunition stored in the ammo drums is fed to the cannon via a rigid, and then via a flexible feed. In such case, the distance covered by the ammunition between the storage and the cannon is long and complicated, which forces the Navy to apply additional space-consuming elements, also increasing the weight of the cannon. Some systems do not use belt-feed system which is replaced with a revolver-like solution. However, such design also has its disadvantages, as it cannot be fed with ammunition of a single type, from one side.

The sensor package of the Integrated Tracking System includes a daylight camera, FLIR system and a laser rangefinder, with a high measurement frequency (above 10 Hz), which makes it possible to act against fast moving, airborne targets. The device also utilizes the IFF IKZ-02 interrogator, which is being manufactured by the PIT-RADWAR company.

The whole system is contained in a housing with a stabilized azimuth and elevation drive system. The visual signal from the cameras, after it is processed by the video-tracker, is used for the purpose of developing automatic target tracking by the system. The optronic sensor may be operated within the -10° to +85° range of elevation, offering n x 360° azimuthal coverage, with a top rotation speed of up to 3 radians per second.

The whole module weighs around 350 kilograms, which is understandable, considering its dynamic parameters and tracking precision. Moreover, elements of the ZGS 158M system may be used to install an optronics-coupled tracking radar in the future.

No decision has been made to install the optronic tracking system on the turret. A separate module has been created instead. Not only do these solutions eliminate the vibration-related disturbances when firing, even though the vibration, in case of the KDA 35 mm cannon, is minor, but they also limit the impact of the combustion gases produced during the shooting process, which may interfere with the target image.

Moreover, the optronic system itself may also be used independently from the cannon, as a CCTV surveillance suite.

The main fire control station comes in a form of a multi-function console housing the fire control system, desktops for the cannon, optronics and power supply and communications, manipulator, two screens (one for radar imagery, one for the integrated tracking system visual feed and subsystems status), videotracker and vision signal fusion block.

Should a specialized fire control radar be missing, the top display may be configured in coupling with the navigation radars which, currently, not only do have an ability to detect the sea-borne targets, but they are also capable of tracking e.g. the helicopters. The monitor may be also connected to the CCTV cameras of the ship, showing the deck around the cannon, raising the level of safety for the crew.

The whole system has been created in a way which makes it possible to embed it within the integrated battle suite of the modern vessels. Alternatively, it may be operated independently, e.g. in case of the older vessels, such as the ORP “Kaszub”.

Reserve fire control station doubles the functions of the main station, it includes a column with a ring sight, desktop, communications system, angle indicator, and a display showing the status and parameters of the system, along with a joystick which features the trigger button. Designers of the AM-35 system significantly expanded the solutions implemented e.g. in the Russian Kolonka-221 optical sight used with the Russian AK-176 and AK-630 cannons.

Thus, the reserve fire control system may be used to carry out preliminary indication of the target, which is the recommended use of this element of the whole weapons system. The “column” provides the operator with a much wider field of view, if the observer sitting under the deck has no observation radar at his disposal. It is a solution which is similar to the ones applied in case of the land-based platforms. There, should no radar be applied, a WPO device is used, being a fusion of binoculars with two encoders which make it possible to recalculate the position of binoculars into position of the object.

What’s next for the system?

The ordering party’s decision to install the AM-35 cannon onboard the ORP “Kaszub” corvette made it possible to start the programme a year before a decision was made to create the 601 design Kormoran II minehunter. In any other case it would be difficult to synchronize these two parallel programmes, especially in the light of the fact that the work on the cannon was to be finalized by 18th December 2015. The deadline has been prolonged ultimately until 18th September 2016, which is still a date placed well before the ORP “Kormoran” vessel prototype is to be handed off.

Selection of the ORP “Kaszub” vessel was also connected to the need of implementing a modern system onboard an older vessel, which forced the consortium to carry out expansive adaptation of the ship, with no connection with the programme.

The prototype Kormoran II minehunter is going to receive the ZU-23-2MR Wróbel II AAA system, and later this weapon is going to be replaced with the newly designed 35 mm cannon. The initial examples of the 35 mm weapon are going to be installed, without any intermediary stages, onboard the series-manufactured minehunters.

So far, the official declarations related to the 35 mm cannons end with the minehunter. Meanwhile, Poland is going to proceed with several maritime programmes, within which the results of the work financed by the National Centre for Research and Development could be implemented (total cost of the project is contained in an amount of 38.6 million zlotys, where PLN 34.354 million was provided by the centre). This concerns both the coastal defence vessels (“Miecznik”) as well as the three patrol/minehunter vessels (“Czapla” class). We should also take into account the fact that the Polish Navy is also willing to build reconnaissance and supply vessels, as well as a tanker. Considering the current asymmetrical array of naval threats, such armament could be very useful.

Land-based anti aircraft system issue also remains open. The politicians are focused on the SHORAD Narew and medium range Wisła systems. However, we still do not know whether the Armed Forces would decide to acquire more 35 mm artillery system, or whether the older 23 mm calibre is still going to be used, including systems such as ZUR-23-2, ZU-23-2 or ZSU-23-4MP Biała. At the moment the Polish Army is planning to acquire the combined missile-AAA Pilica systems, fitted with a 23 mm cannon, the purpose of which is to protect the airbases. The Armament Inspectorate also initiated a market analysis in January, pertaining to the AAA which was to utilize the programmable ammunition. The issue of prospective armament for the air-defence units of the land forces still remains an open question.

There is no specific action plan in place, which would ultimately determine the path of development for the Polish anti aircraft systems, making it possible to accelerate and finalize the works on the programmable munitions. The ABM ammunition programme is being pursued outside the “35 mm naval cannon” initiative by MESKO and PIT-RADWAR. So far, such ammunition for the AAA is not listed as one of the priority goals contained within the Polish Army’s modernization programme.

Not only was the selection of the 35 mm cannon for the Loara system dictated by the analysis carried out in Poland, but it was also largely based on the foreign trends. At the time, works were being carried out on a “universal anti-aircraft calibre”, and there was a search executed, the aim of which was to develop an AAA system which would have its properties optimal when it comes to its combat capacity (range and effectiveness), as well as weight and integration options with a variety of carriers.

The experts stress the fact that the AM-35 system could only have been developed so quickly due to the fact that some time ago investments were made concerning the Loara programme, which required a lot of workload and funds. The system shows that it is very important to maintain continuity of the R&D stage. There is no option of developing new technologies in so short period of time, with limited funding, without a long-term programme in place.